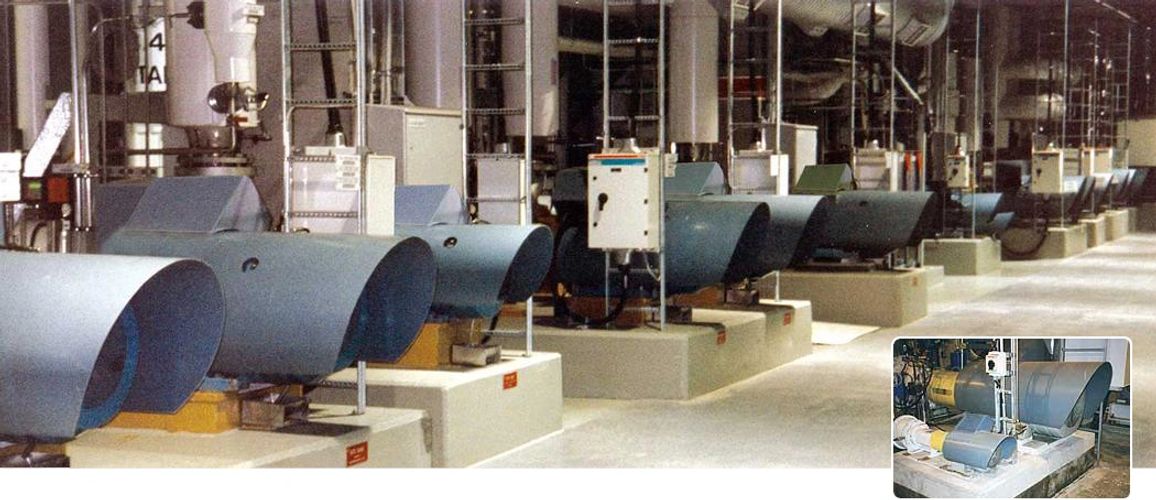

Protect your motors from debris with our cooling covers.

1. The perfect solution to decrease production costs with electric motor covers.

2. Cool and shield electric motors significantly reducing electric motor rewinds and replacements.

3. Virtual cooling tunnel. RexMotorCover™ creates a "virtual cooling tunnel" which lowers motor operating temperature. A 10°C or 18°F reduction in motor operating temperature can extend motor winding life by half.

4. These innovative electric motor covers are responsible for saving individual companies hundreds of thousands of dollars each year on motor maintenance and downtime costs. electric motor covers

5. RexMotorCovers™ are standardized for any NEMA and IEC frame size.

6. Flexibility, durability, and lightness makes for fast and easy installation. Removal for motor maintenance is fast and simple.

7. RexMotorCovers™ perfectly shield electric motors from hot, wet, corrosive, dirty, and other weathering conditions that immediately or eventually damage and burn motor windings.

8. RexMotorCovers™ have excellent resistance to chemicals, and they are non-conductive as they are made out of special fiberglass reinforced plastic.

9. There are hundreds of mills using hundreds of thousands of motor covers for the same reason.

Rexxell Corporation

2516 Waukegan Rd. #139, Glenview IL 60025